The New Mobility challenges of self-driving, connected and environmentally sustainable vehicles have led the automotive industry to expand the use of hot-stamping technology to structural car metal sheet parts.

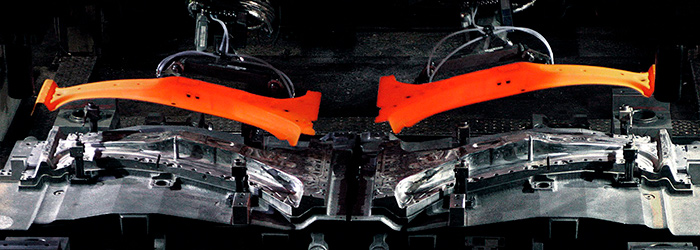

Press-hardening / Hot stamping technology helps the automotive industry meet the above goals in terms of lightweight and safety by creating stronger, lighter components with high strength, high geometric complexity and excellent form accuracy in a single stroke.

However, the hot-stamping process creates a harsh working environment (solid-liquid and rust contamination) that significantly reduces the lifetime of gas springs and standard die components.

Thanks to 15 years of field experience in hot-stamping applications on most OEM / TIER 1s, AZOLGAS can offer widely tested and suitable technical multi-technology (gas-hydraulic-pneumatics) solutions for hot forming.